Origin

From the outset, SIPREM has been an Independent, Family, Human Company.

A practical man above all, it was by creating SIPREM officially in February 1974, that Raymond Martin achieved his true profession as technician and creator.

He was then developing the controlled and managed Automatic Pressure Gelation process (APG), for production manufacture.

A process in which he was also in at the origin, as engineer responsible for industrialisation at one of the leading Epoxy Resin manufacturers.

Our Team

A man with good connections, Raymond Martin knew how to share his enthusiasm and from 1979 transmit his know-how to his son Christian Martin, the current CEO.

With the family spirit to the fore, in 1993 Elisabeth Martin succeeded Josiane Martin, taking over the company's Finance and Administration Department.

The spirit of the company and its growth require the presence of a competent, motivated engineer. So in 1995, Jean Luc Charnay came to strengthen the team and inspire new technical development.

Without forgetting all the faithful Mechanics, Compounders and Moulders, with the oldest going back to the 1980s.

The wish to pass on both our knowledge of Electrical Technology, and our skills in Resin Moulding have allowed us to rejuvenate the team over the last five years by recruiting Electrical Engineers and Technicians.

Production Resources

From the beginning SIPREM has been actively engaged in improving manufacturing processes, their reliability and traceability.

This in order to make ever more complex, high performance parts.

Modular Compounding Station

Comprising 12 Mixers under Vacuum

Capacity from 20 litres to 200 litres

Allowing great freedom in preparing different Compounds, in both the resins used, and the incorporated loads and added colouring.

SIPREM designed automatic cleaning system, providing maximum health and safety for the operators.

Manufacturing Stations

A set of 13 Semi-Automatic Horizontal Presses

Heated Plates range from 400 x 400 to 1,100 x 1,100

Openings range from 650 to 2,800

Multi area temperature regulation

Numerical assistance to moulding for all operators

Sequence controller on each press

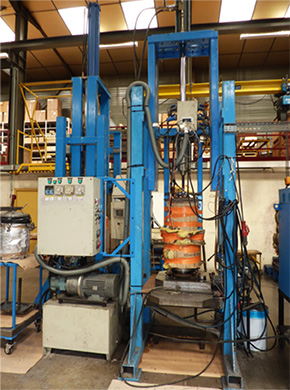

A set of Vertical Semi-automated Presses

Identical principles to Horizontal Presses

A set of Moulding Equipment under Vacuum

Vacuum chambers range from 0.3 to 5 m3

Programmable and regulated ovens range from 0.5 to 15 m3

Mechanical Workshop

Provides all maintenance for our manufacturing stations

Maintenance of our Environment and Equipment (Presses, Compressor, Vacuum pumps...)

Machining epoxy products

and being able to react to an urgent requirement by producing prototype tooling, inserts...

Inspection Resources

The Quality Assurance of our services is closely linked to our willingness and equipment

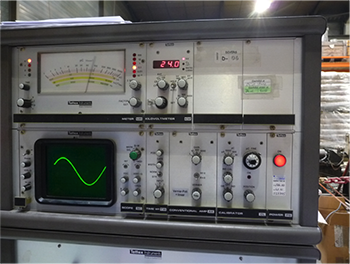

Electrical Tests

Dielectric Strength tests up to 150 kV

Partial Discharge Tests:

Level to < 2 pC. at 50 kV

Platform for lightning impulse tests up to 250 kV

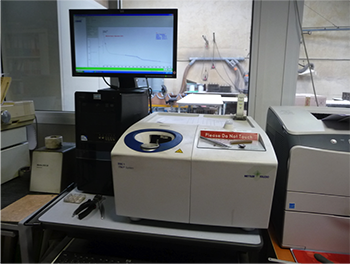

Physical and Chemical tests

2 DSC analysers (for example, for Glass Transition Point checks)

Mechanical Tests

Tension test station

Specimen Bending test equipment

Tightness inspection

Pressure resistance check

Metrology

Marble

Measurement Column

Three Dimensional Inspection in partnership with a local company

About the Products :

- Comply with standard CEI 61243 - For Insulators

- Comply with standard HN 41-E01 LCIE certificate 183128 - For certain Sipremites

- Comply with standard EN 60695-2 - Certificate no. 10970 - Incandescent wire

- Comply with standard NF F 16-101 I2-2 - Certificate no. 10096 - Fire Behaviour

- Comply with standard STMS-001 - Certificate no. 10096 - Fire Behaviour

- Comply with standard NF F 16-101 Certificate no. 10129 - Smoke Rating

- IP 68 classification Certificate LCIE 447 195 - For our Transformers

About the Company

- SIPREM has been certified to standard ISO 9001 - Since 2006 (Version 2008 Today)

- SIPREM has been certified to standard ISO 14001 - Version 2004 since 2013

- SIPREM has been certified to standard OH SAS ISO 18001 - Version 2007 since 2013

In Progress

- Very close REACH Regulation monitoring by our QSE Manager.

Area of Activity

| Medium, High and Very High Voltage Electrical Technology | 82% |

| Radio Telephony | 7% |

| Rail Transport | 5% |

| Nuclear | 4% |

| Work in Aggressive Chemical Environments | 1% |

| Radiation | 1% |

The Life of SIPREM in figures

| Age: | 40 years |

| Personnel: | 30 |

| Average age: | 40 years |

| Average turnover over 5 years: | €3.5M |

| Covered area:2 | 3,000 m2 |

| Total area:2 | 8,700 m2 |

Voltage Range for our Products

From 5.5 kV to 600 kV.

From 100 A to 6,300 A.

To satisfy you and continue to satisfy our customers,

- By the ability to give you technical support,

- By the Quality of our services,

- By complying with stated delivery times,

- By our Availability

Our Experience and our Knowledge allow us to support you from the start of the creation of your product,

to provide you with advice on the choice of appropriate resins and the definition of the production tool.

Our Goal:

To be and remain the highest performance, without ever neglecting:

TECHNICAL QUALITY.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|